Bentonite based LCM

Advantages:

- Wide range of materials

- Adjustable setting time

- Optimal flow properties during injection

- Good adhesion to the rock

- Great penetration into the porous structures

- High degree of stability

- Does not react with oil and easily removed from pores

- Injected through bit’s nozzles

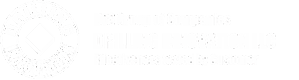

Application:

- Losses isolation - from partial to total losses

- From normal till formation abnormally low formation pressure and fracture gradient and in a wide temperature range

- Losses curing where is required a control of hardening time

- Curing long intervals complicated by intensive crack’s structure

- On construction of horizontal – directional wells

- Alignment of injectivity profile for oil recovery jobs

Download PDF catalogue

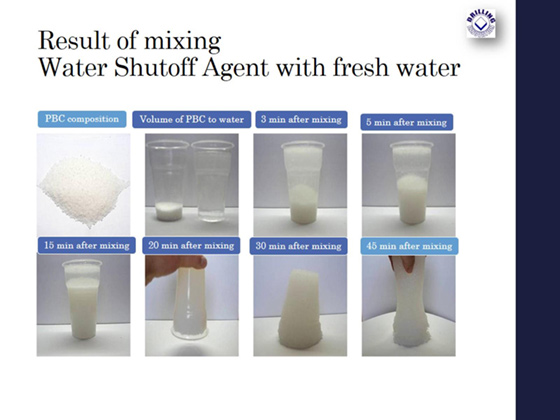

Water Shutoff Agent PBC

Application of Water Shutoff Agent PBC for lost circulation zone’s isolation in drilling, as well as for isolation of behind-the-casing flows in casing repair due to a number of its physical and chemical properties of polymer composition:

1. finely dispersed material with bulk density 68.67 – 81.16 lbm/cu.ft;

2. polymerized in the lost circulation zone in contact with water;

3. polymerization time is about 1 hour and can be easily regulated (from 15 to 120 minutes);

4. increases in volume of up to 20 times during polymerization;

5. high adhesion to the rocks surface;

6. resistant to hostile environment after polymerization;

7. does not react with oil in formation and easily removed from the pore space.

Download PDF catalogue

A selected well must meet the following geological and technological requirements:

• temperature in a lost circulation zone should no more than +130 C;

• intake capacity in a lost circulation zone should be no less than 650 bbl /day at a pressure of 440 psi.

Technology is most applicable in fractured or in terrigenous reservoirs with catastrophic absorption (from 6 bbl per hour to irrevocable circulation) and also for isolation of behind-the-casing flows in pumping and production wells.

On well no. 26 Platovskaya at a 5604 ft. depth a drilling team met a gap 2.3 ft. The intensity of absorption was 176 bbl per hour. The lost circulation zone was not drilled out completely due to lack of drilling mud. 826 lb. of PSC slurry was pumped in lost circulation zone. After the reaction the circulation was restored and further drilling of lost circulation zone was continued till 5633 ft. depth. The partial absorption was 18bbls/hr. After the injection of a viscous tampon in volume 48bbls absorption ceased.

At the borehole № 1 Danilovskaya at a depth of 499m there was a full absorption flushing fluid. While washing the intensity of the absorption 200bbls/hr. Produced for composition PSC -rocking material in the amount of 300 kg, the circulation was restored. The drilling was continued with the partial absorption 18 bbls/ hour, but at a depth of 520 - 525m it has been met the total loss and the static level in the borehole was 72m. The pumping of High Viscous Pills did not give any results. Then it was pumped into the absorption zone the composition PSC suspension of the material in the amount of 300 kg and 90bbls of viscous tampon. With further deepening of wells absorption intensity was 18 bbls/ hr. From a depth of 605m the absorption intensity decreased to 6bbls/hr, then absorption had ceased.

The biggest complication in our place on the borehole № 1 Shapkinsky. When drilling at a depth of 3113m was an increase ROP, the intensity of the absorption was 30m3/hour at the level of 60m. Made to the deepening of 3118m, the absorption intensity has not changed. The elimination of the absorption inject swab positive result did not give. composition PSC suspension was pumped material in the amount of 300 kg, after the reaction continued drilling with partial absorption 12 bbls/hr. With a drilling depth of 3120m the absorption intensity increased to 30bbls/hr. A composition PSC suspension was pumped material in the amount of 200 kg and viscous tampon in Quantity 60bbls, after the reaction continued drilling. When drilling in the interval 3330-3335m there was a partial absorption flushing-component fluid to 18bbls/hr. In the absorption zone pumped suspension PBS in the amount of 220kg and a viscous tampon. Absorption of dismantled. With further deepening of the well there was a partial absorption of washing fluid at a depth of 3390m. In the area of absorption under pressure pumped 300kg suspension PSC, after response within 4 hours of continued drilling, partial absorption was 1.2 bbls/hr.

At the borehole № 2 Tersinskaya. During the drilling of wells at a depth of 1365m well absorbed completely. No exit circulation hole deepened to 1366.4m. After changing the layout of the bottom of the drill string, through the bit, installed at a depth of 1358m pumped 310kg PSC composition. Downloading composition PSC as performed at a pressure 40 - 45kgs/sq.sm. After of Technology parking lot washing fluid absorption were noted.

As can be seen from the above examples, the using of PSC material particular advantage to significantly reduce the time and cost of materials for elimination of lost drilling fluid.