Attempts to drill to the required depth during well construction sometimes fail because of lost circulation zone, sloughing and swelling. Such problems often re-sult in numerous isolation jobs? Sometimes require shutoff isolation jobs, sometimes require shutoff of problem intervals with intermediate casing strings and liners with the resulting loss of wellbore diameter, more complicated wellbore designs, increased consumption of casing and cement, added cost and cement. Unknown or incorrect depth formation of incompatible formation can bring errors in casing string length or set point and create similar problems. Sometimes separate casing strings are used to isolate formations, which are incompatible under drilling conditions, even if the zones are thin or a short distance apart.

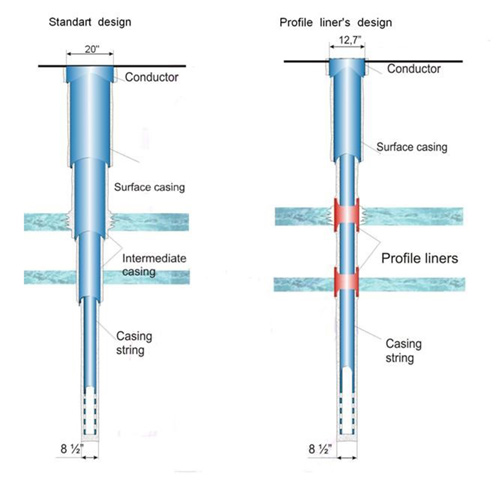

There is a unique technology, allowing for local isolation of formations, using steel casing run in the lost circulation zone, without cementing and without loss of wellbore diameter.

This unconventional technology, which has got the name of expandable profile liner employs steel casing made from a proprietary alloy with the diameter exceeding the hole size. The expandable profile liner is profiled through its length to allow for free run in the lost circulation zone. The wellbore in the problem zone interval is enlarged by expandable under reamers to the external diameter of the initial nonprofiled casing string. After that the expandable profile liner is run into a place across the lost circulation zone with a designed for purpose bottomhole assembly and drill pipes. Once the expandable profile liner is in place, drilling mud is injected, thus creating pressure to straighten and to inflate the profile liner to the full working diameter of the wellbore. After the profile liner has been tightly pressed against the underreamed formation face, a specially designed expander is run through for final sizing of the system. The profile liner uses packer elements to establish a seal with the casing above and at the end sections.

Thus the expandable profile liner technology includes the following of basic operations:

- enlarging of hole diameter with expandable underreamer;

- running of expandable profile liner on drill string;

- expanding of profile liner with internal mud pressure;

- expansion of cylindrical ends of profile liner with expander.

Expandable profile liners have been installed in more than 1400 wells as an alternative to running intermediate casing strings and successfully solving lost cir-culation and well bore stability problems in various regions of Russia.

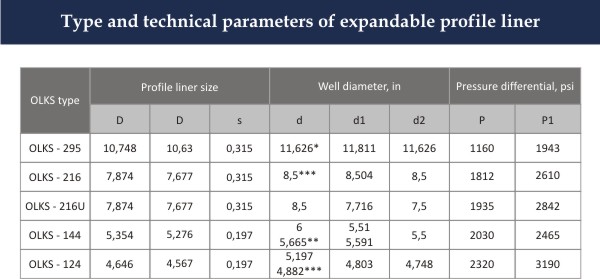

D - diameter of profile liner across cylindrical ends;

D1 – diameter of circle circumscribed around profiled portion;

s – wall thickness;

d – well size before installation of profile liner;

d1 – profile liner ID after installation;

d2 – bit size used for further drilling after profile liner installation;

Р – expansion pressure;

Р1 – maximum allowed internal pressure on profile liner

* - hole is being reamed to 12.598 in size ;

** - hole is being reamed to 9.331 in size;

*** - hole is being reamed to 6.063 in size ;

**** - hole is being reamed to 5.276 in size.